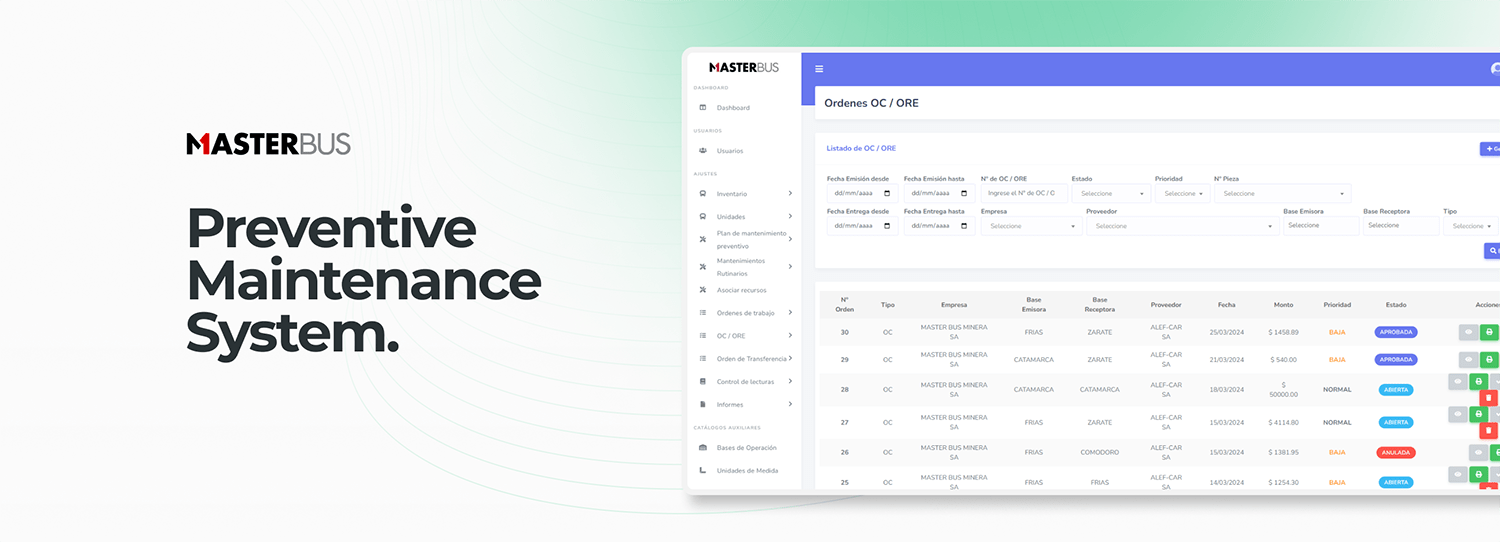

Masterbus: preventive maintenance system

Customized management system for the maintenance of your transport fleet

The system allows for the organization, management and planning of routine preventive and corrective maintenance on transport units, as well as on equipment used for maintenance and on the bases they have in the country.

Customer

Masterbus manages the maintenance of its units that transport more than 27,000 people annually throughout the country in which the company operates.

The system allows for the ordering, administration and planning of routine, preventive and corrective maintenance on transport units, as well as on equipment

used for maintenance and on the bases they have in the country.

Situation status

We developed a multi-modular system for planning maintenance at user-defined deadlines to have a projection of expenses and operations.

Project pillars:

- Continuous improvement (LEAN)

- Process standardization (LEAN)

- Search for waste elimination (LEAN)

Methodology:

We apply Scrum, an agile methodology that allows us to improve the efficiency and quality of the product delivered. 34 development sprints were carried out to put it into production and the project is continued with a subsequent stage of continuous improvement.

Our work

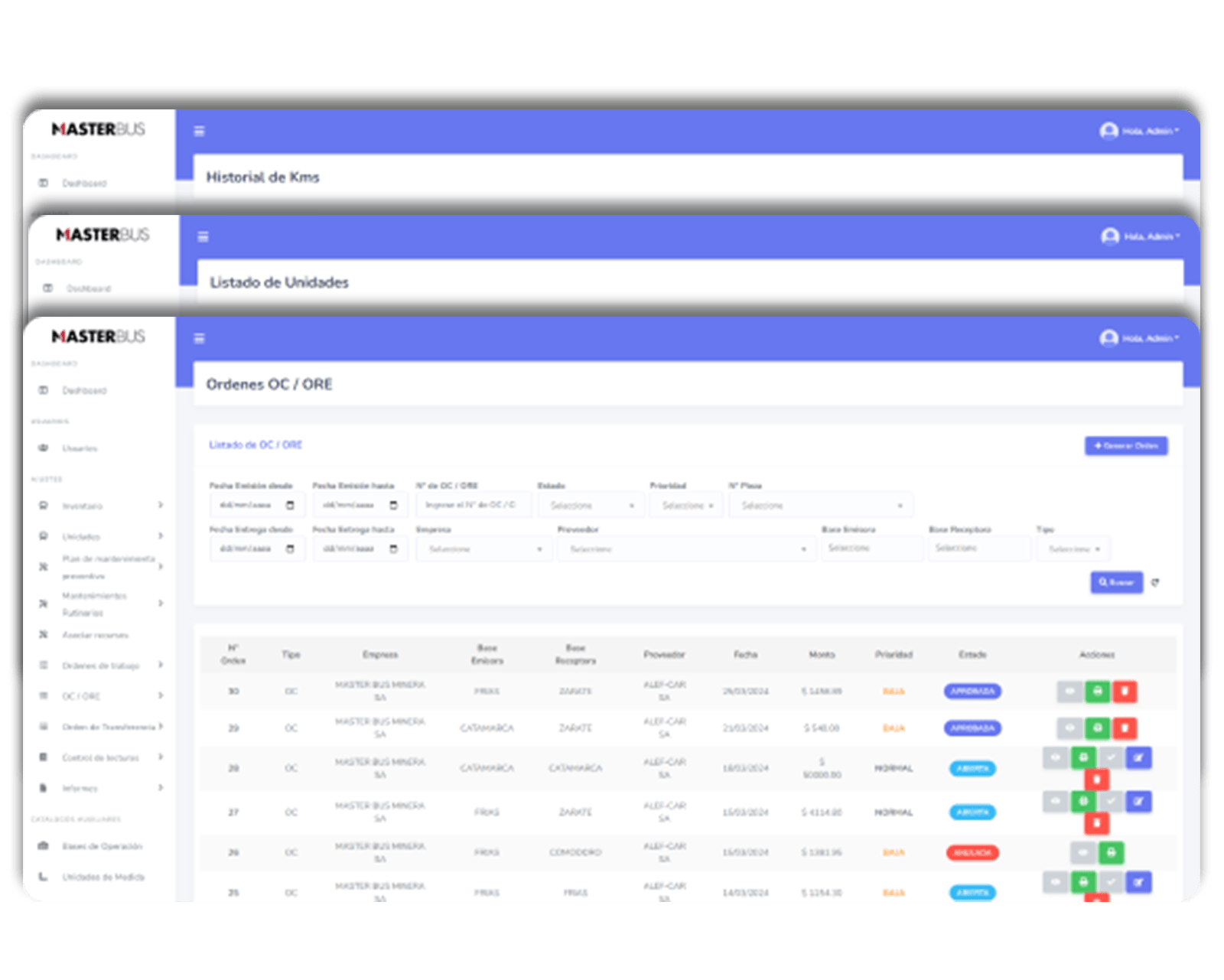

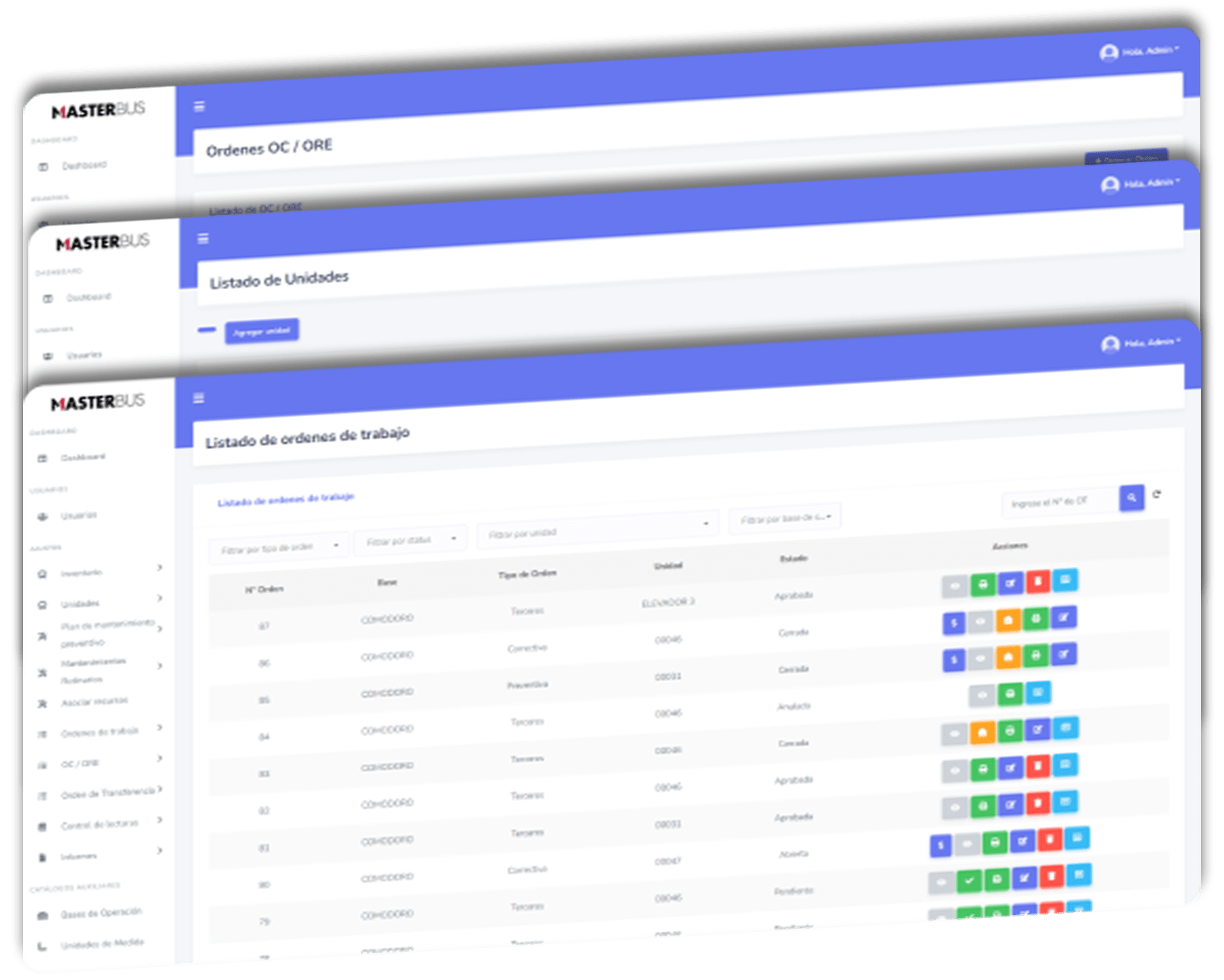

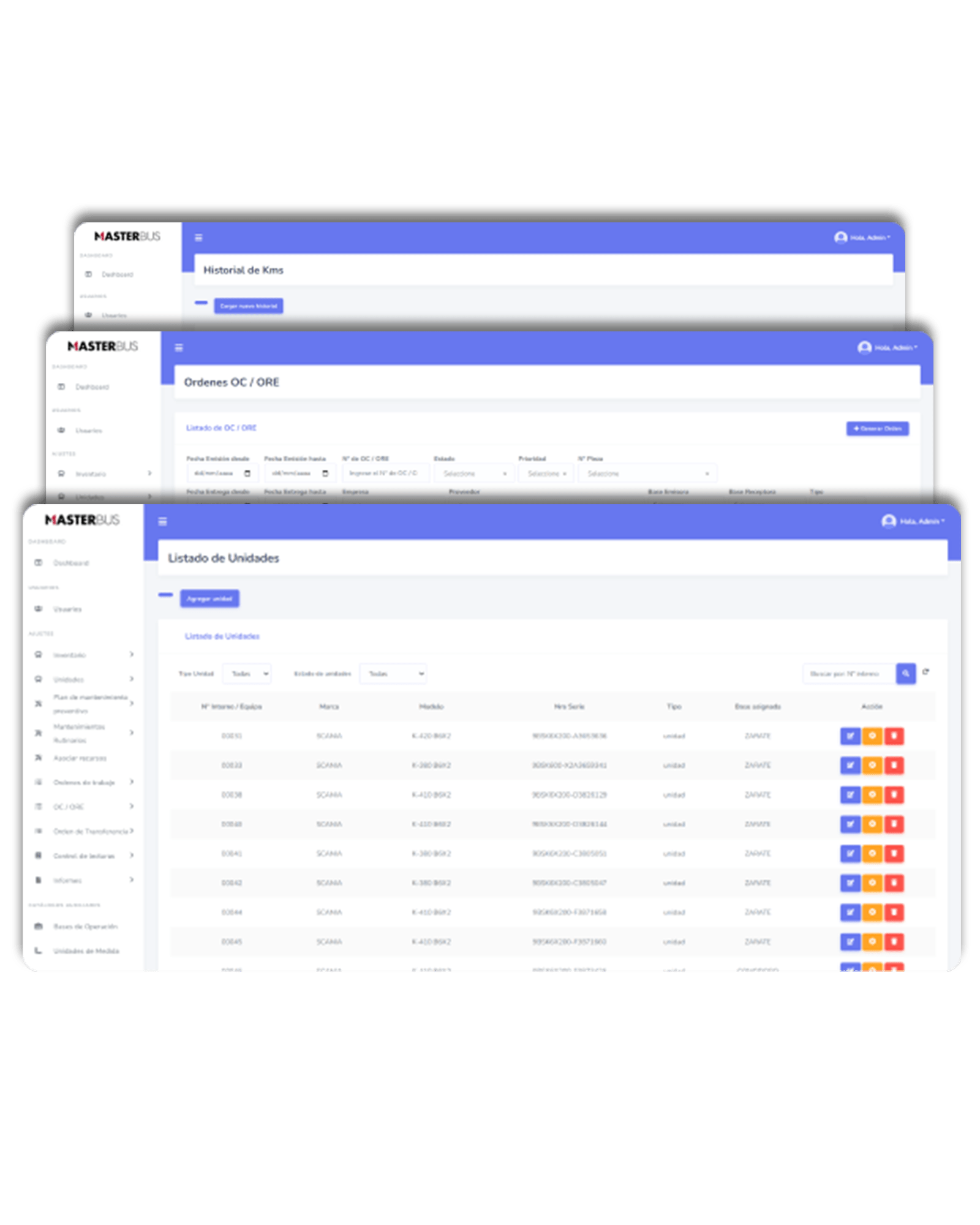

Modules

Work orders to be carried out, user and permission management, parts and inventory management, maintenance planning (preventive and routine), purchase management, movement of stock and units between bases.

User roles for management:

The system is designed for different user levels. On the one hand, there are internal users who are those who work in the maintenance area of the organization, and perform different maintenance tasks (cleaning, mechanics, bodywork, electricity, storage, etc.) and on the other, suppliers can also access to check current or future needs for high-consumption parts.

Reports:

On times, expenses and comparison of work orders on the total number of units and

individually. Operational reports.

ABM:

Bases, units of measurement, catalog parts, supplier management, brands, models and types of vehicles.

Testimony

We share a chat with Osvaldo Gurevich, Head of Maintenance, Industrial Safety and Environment of the company, who tells us how our custom developments complement their operations.

Let’s put your idea into motion

Let’s chat about your idea to bring it to life and enhance it